|

THE

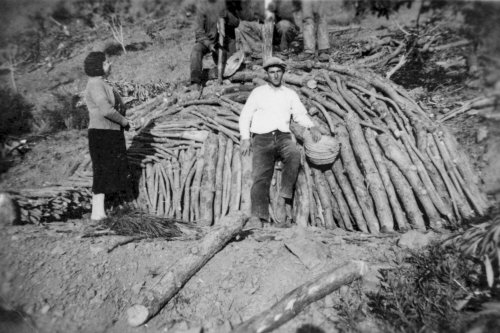

CHARCOAL BURNERS

One of the most established occupations in

the region was that of charcoal burner. The

charcoal burner undertook very hard work in

all weather conditions. During the

production of charcoal, there was no time to

sleep or rest. Day and night, the charcoal

burner had to control several ovens in

different stages of the process, demanding

constant vigilance.

The charcoal burner had a ghostly

appearance, with a face obscured by charcoal

and clothes torn by firewood. His diet was

not varied and his workplace was the

woodland. Despite the gruelling nature of

his work, the charcoal burner was a person

who accepted his position with dignity.

Obtaining charcoal

The preparation of the firewood depended on

its type and the place in which it was

found. Wood from pollarded trees (Cork Oak,

Chestnut, Portuguese Oak, Red Oak) was

obtained by cutting the tree through the

trunk and once felled, pruning the branches

and cutting up the trunk. In the event that

branches were used for firewood (rock roses,

junipers), the tips and thin branches not

suitable for making charcoal were removed.

Next the ground used for charcoal

manufacture had to be chosen and prepared. A

pit was dug in roughly circular form. The

floor of the kiln had to be compacted down

to prevent air entering through it since the

presence of air currents would make it very

difficult to control the fire during

charring.

Once the floor was cleared and the firewood

placed close by, the kiln was prepared and

set up. First a stake was set vertically

into the centre of the circular hole. Next

the wood was placed around the stake forming

a cone, trying to distribute it uniformly so

that cracks would not appear whole being

roasted.

The kiln was covered with a layer of

bracken, turf, moss or dead leaves. At that

point the stake placed in the centre was

removed and the hole (the future chimney)

was covered to prevent the earth from the

top layer falling in. The exterior cover

insulates the wood from the outside, so that

the oxygen in the air does not ignite it. A

correct charring is simply the slow and

incomplete combustion of wood due to lack of

oxygen.

Close to the kiln a small fire was lit, and

the hot coals obtained were thrown into the

mouth of the kiln. Once the fire reached

sufficient strength to not go out, the

chimney was capped, first being covered with

bracken and then by earth. From this point

on, it all has to be carefully watched,

particularly during the first ten hours,

which is when the clamp to burn. During the

charring process, the wood reduces in

volume, so it has to be beaten down and in

this way the charcoal already produced is

compacted to reduce the gaps that are

produced.

If the roast is too fast, the charcoal

burns, leaving only cinders. If the roast is

too slow, the charcoal would not be evenly

cooked, giving only partly charred wood. For

these reasons, the charcoal burner would

have to open ventilation holes in the parts

where the temperature is less, and block off

the areas where the temperature was higher,

trying to achieve a uniform intensity of the

fire at the different heights of the kiln.

The burning process occurred from the top

downwards, and from the centre outwards. The

duration of this process varied, depending

on the size of the kiln, taking around one

week.

Once the roasting was completed, the kiln

had to be extinguished and cooled, for which

the burnt earth was removed in order to

cover the ventilation holes and in that way

put out the small pockets of fire that were

still burning on the inside.

The only thing left was to bag up and

transport the charcoal. The charcoal burners

themselves packed it into a bag, closing it

with a piece of string stitched through the

mouth of a sack. Finally, they carried the

sacks on their backs to the loading area.

The most usual form of transport was by

pack-animal, driven by muleteers, taking the

charcoal to their destinations.

|